Wood comes from timber, and timber comes from tree. All the timber we see around us isn’t suitable for door, frame or furniture manufacturing. Some timbers are suitable for the frame, and some are for the door, there are timbers suitable for door and some are suitable for frame only. Furniture can be made of any timber which is durable and strong. Frames are usually made from strong and durable timbers, shutters may be replaced any time if needed but, frames are difficult to replace, they are installed in the wall with 6 or more clamps, and then maybe decorated with wall tiles, wallpapers or wooden wall decoration. We need to use properly seasoned strong and durable timber for the frame, Chittagong Shill Karai is the most durable for the frame, Burma teak, teak Chambul, Chittagong teak and Mahogany are suitable and durable for frame making too. Some of the timbers aren’t suitable for door manufacturing, due to their excessive weightless durability and poor outlook, the most suitable timber in Bangladesh is Burma teak, Chittagong teak, Teak Chambul, Chittagong Gamari and Jessore Mahogany. Since the quality of timber depends on the area where the timber came from so, we need to add the name of the area before the name of the timber, like Jessore Mahogany.

For commercial usage, since we need a lot of timber, we need to find timbers from those areas where high-quality timber grows and easy to collect, there are other timbers they are good durable and popular but, difficult to collect and highly-priced. Quality of the timber depends on the geographical areas which we already have mentioned earlier, also there is a huge difference between naturally grown timber in the yard, and commercially harvested timber. Naturally grown timbers in the yards usually got broken branches, nailed by the owner when needed to hang a rope or break a branch by the children to clean their teeth, goat or cow eat up a branch. In this kind of situation plants get new branches grow off the broken part and the steam of the plant becomes shorter. Since the plant is getting a lot of sunlight surrounding it, branches of the tree grows with the same ratio as the steam branch. Steam of the tree grows shorter and so is the quality of the timber get poorer. We find a lot of problem in sawing the timber in the sawmill, most of the time we find nails inside the timber, the nails are in so deeper, it’s difficult to identify them even with a handheld metal detector, it don’t only damage the sawmill blade, it damages the special blades which shape and cut the bits, tanning blades and so is the mortising. It’s easy to collect short timber but, difficult to find long ones. Manufacturing a door and a frame, more than 50% of them is 7’ long timber and the rest of them is less than 7’ with different sizes.

Making a frame we need two 7’ long 2.5” X 6” X 7’ and one short piece for the top. For a Door we need the same two 1.5” x 6”x 7’ pieces of timber is called style, and the other short pieces. It is risky to use locally grown timber in the yard or by the road, for door and frame manufacturing. We need a lot of timber every day for our door and frame manufacturing, which is very difficult to collect yard growers.

Since our target is to get high quality and bulk quantity timber, we need to depend on the commercially grown timber; they plant their tree in a certain distance to make sure the tree will have a certain amount of light from the top part of the tree so the tree will grow longer and straighter. While they are little plants cut their branches off to let the tree grow vertically, so we will get a tree with longer steam, which will provide us, high-quality timber with straight fiber, which will not bend easily and provide us with high-quality fiber. Since the commercial harvesters harvest them for commercial purpose, they always maintain necessary water content in the soil, use necessary fertilizer, which they learn from the forest department, they teach them to cut the brunches off so the tree will grow longer and straighter, and produce high-quality fiber. Since we need a lot of lumber every day it’s essential to collect the timber from commercial timber grower, where it’s easy to get a lot of matured and high-quality timber.

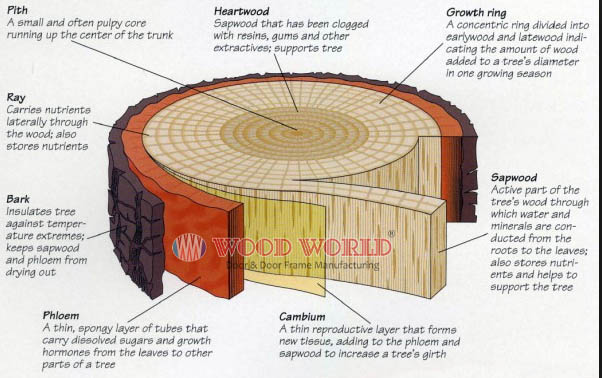

Maturity is another most important factor in wooden product manufacturing, maturity can be measured in terms of the age of the tree, sometimes it doesn’t work that way, age of a tree doesn’t always give a matured tree, soil, weather, planting process, and maintenance is the key reason for the early maturity, this is most beneficial for the timber grower, manufacturer and the user.

Maturity is another most important factor in wooden product manufacturing, maturity can be measured in terms of the age of the tree, sometimes it doesn’t work that way, age of a tree doesn’t always give a matured tree, soil, weather, planting process, and maintenance is the key reason for the early maturity, this is most beneficial for the timber grower, manufacturer and the user.

Most of the people are helpless, identifying quality timber; they come to us for a quality Door and Frame. When clients come to us for help, it’s easier for any manufacturer to misguide some of them. When they come to us they feel so helpless, they express their helplessness and ask for our assistance.

Since wood is our main raw material, so the quality of our product directly depends on the quality of our timber. This is the step we approach very carefully, the first thing we consider is the area where the timber came from, and then the maturity is the most important thing, doesn’t matter whether the timber is from the best area where certain timber is most suitable to grow, without the maturity of the timber it contains no value.

After we get these two things right, the next thing is sectioning the timber properly, otherwise, we may waste a lot of wood before we make the sections, we need to know exactly the lengths we need whether for the frame or the door. There is another thing we need to remember, we will try to section the timber to make sure we don’t have a bend or the section is not bowed but, they got to be in the measurement where we don’t have unnecessary length, which may cause unnecessary wastage of material.

Sawing is another most essential part in this line of business, if anyone starts this business not knowing what is he is doing, may lose his capital within no time. Thickness and width of the timber are the vital most after sectioning, suppose we need 1.5” for the final product, what size do we need to say? The same thing for the frame, we need 2.25”x5.75” exact thickness and width of the final size of the timber, what size do we need to say, we will be losing some material for the cutting thickness, altogether if we saw the timber oversize we will lose money and will have to plan too much material out to come to the original size. Oversizing the timber is less risky than cutting the timber under-sizing, if we undercut the timber that will be a total disaster, we will lose the whole thing, whole material is wastage, lose the entire investment within no time. Even the width of the timber got to be cut right, if not may have to lose the entire investment.

For thickness of any material we need to cut 2/8” of an inch thicker than our desired final production thickness, 1/8” of an inch for the saw blade to cut and another 1/8 of an inch for jointer and thicknesses.